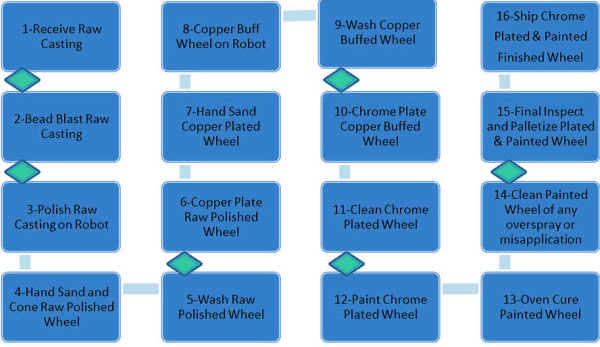

1 |

STEP ONE

|

2 |

STEP TWO

|

3 |

STEP THREE |

4 |

STEP FOUR |

5 |

STEP FIVE |

Desmut

Copper Bath

6 |

STEP SIX |

7 |

STEP SEVEN |

8 |

STEP EIGHT |

9 |

STEP NINE |

10 |

STEP TEN |

11 |

STEP ELEVEN |

![]()

Each green diamond denotes one

of the six points of inspection.

Copyright © Kentucky Chrome Works. All Rights Reserved. Web published by Marketing Options LLC