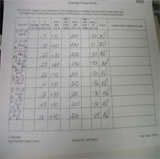

RAW INSPECTION

All rims are inspected at incoming for shipping damage and visual anomalies. All rims are 100% inspected after raw polishing for copper plating acceptability.

Inspection at all critical areas throughout the process assures the highest quality chrome wheels.

State-of-the-art testing and process monitoring assure highest quality.

Proprietary and patented mechanically porosity sealing process developed by our owner.

CASS TESTING

KCW meets or exceeds all OEM engineering specifications for Copper Acid Salt Spray, Neutral Salt Spray, Thermal Shock, Adhesion & Metal Thickness.

STEP TEST

Step testing assures the metals are applied in the designated thickness and proportional percentages.

MICROPOROSITY DENSITY

Specific microporosity densities are required to assure any minute corrosion is lateral across the face of the rim and not vertical throughthe layers of plating. OEM's specify minimum and maximum pores per square inch of surface area.

THERMAL SHOCK TESTING

the rim to extremes in temperature from sub-zero degree to over 300 degrees F. This exposure will reveal any deficiency in paint and/or plating adhesion.

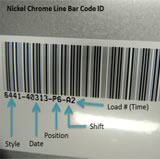

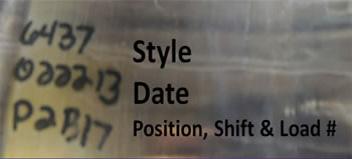

CHROME LINE TRACEABILITY

Should an issue arise, we can trace each individual wheel back to the exact time it came off the chrome line and the exact time it was in a particular bath. Via TrueChem we can create a virtual replay of the plating conditions to ascertain if there were any plating anomalies.

COPPER LINE TRACEABILITY

The copper line process id number is linked to the chrome line process id number. With this link if there is a copper plating related issue we can with the chrome line process id number pull up via TrueChem the copper line plating conditions for the specific wheel.

COPPER INSPECTION

All rims are 100% inspected after copper plating and copper buffing for chrome plate acceptability.

CHROME INSPECTION

All rims are 100% inspected after chrome plating to guarantee acceptability for painting of lug towers, brake side and tire well surfaces.

FINAL INSPECTION

All rims are 100% inspected after paint. Only those wheels meeting OEM appearance standards are designated RTS “Ready to Ship”. Rims not meeting standard are placed in Quarantine for MRB Review.

Paint Overspray Cleaning

Final Inspection

Copyright © Kentucky Chrome Works. All Rights Reserved. Web published by Marketing Options LLC